Thermosetting Vacuum Metalizing Base Coating

Focus on Vacuum Metalizing Coating for 30 Years

SZ-97AAAT Vacuum Metalizing Coating

This product is specially designed for the vacuum coating process, and is widely used in substrates such as PS, ABS, PP plastic modified by pre-treatment, and ceramics. It can be used both as a base coat and as a top coat. The outstanding advantages are high brightness, good flexibility, light color, fast dyeing, excellent adhesion and mechanical properties, quick drying at low temperature, durable glossiness, fulling, good leveling, less pitting, good hand feeling, etc. advantage.

| Packaging Specification | Applicable Materials | Application |

| 14.5kg/drum, 150kg/drum | PS, ABS, PP plastic modified by pre-processing, ceramics. | Base coat, top coat |

| Application Method | Product Characteristics | |

| Spraying | High brightness, good flexibility, light color, fast dyeing | |

Coating Method : Generally, it can be used by spraying directly, and users can also use it after adding an appropriate amount of diluent according to needs.

DryingIt is required to dry at 60℃~70℃ for about 2 hours (the user can adjust the drying time appropriately according to the thickness of the film). In order to make the coating film dry completely, the air circulation in the oven should be kept.

Thinner: If diluent is needed in actual use, it is required to use DA thinner or T-407 special thinner matching the vacuum coating paint, and it is recommended to use Shenzhan special DA thinner.

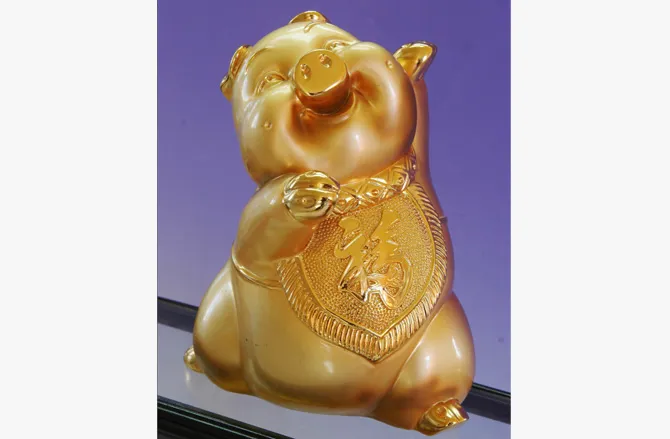

(Products are widely used in toys, handicrafts, Christmas products, lamps and lanterns, etc. For more effects, pleaseContact Us)